Woodworking has evolved significantly over the years, embracing both ancient techniques and modern advancements. This post explores a common dilemma faced by woodworkers: the choice between hand tools and air tools. Each type offers distinct benefits and challenges, which we will compare to help you decide the best tools for your woodworking needs.

Overview of Hand Tools

Hand tools have been the backbone of woodworking for centuries. Key examples include chisels for carving, saws for cutting, and planes for smoothing surfaces. These tools are revered for their precision, allowing artisans to execute intricate details with control that machine tools can’t match. They don’t require electricity, making them portable and convenient for on-the-spot adjustments. Hand tools also connect us to the traditional artistry of woodworking, where every piece tells the story of craftsmanship.

Overview of Air Tools

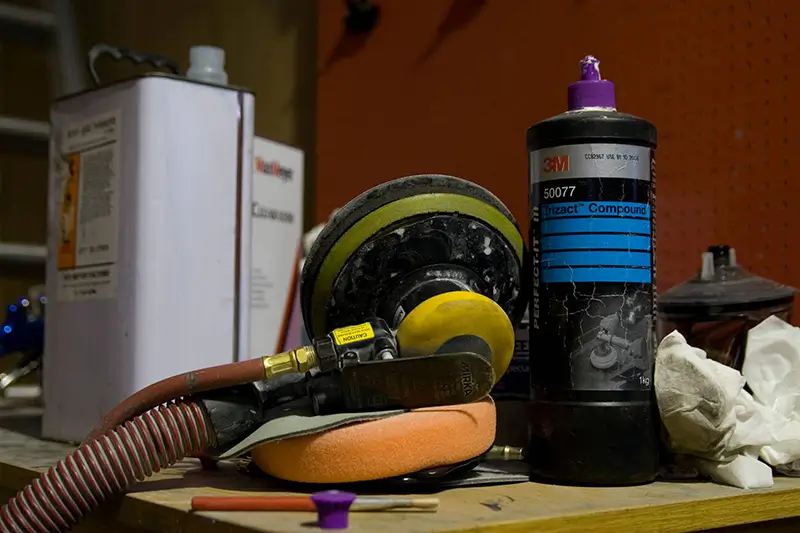

Air tools, powered by compressed air from a connected compressor, include tools like pneumatic nailers and sanders. They are known for their ability to speed up production without sacrificing consistency. Air tools can deliver continuous power, reduce the physical strain typically associated with manual labor, and streamline processes in commercial settings. Their efficiency is particularly noticeable in tasks requiring repetitive motion, such as assembly line production or large-scale constructions.

Comparative Analysis

Choosing between hand tools and air tools often depends on the project’s scale and the nature of the work. For hobbyists or those engaged in detailed crafts, hand tools may be preferable for their control and finesse. In contrast, in a high-volume professional environment where speed and repeatability are paramount, air tools are indispensable.

Economically, while hand tools generally have lower initial costs and require minimal maintenance, air tools, though more costly upfront and needing regular servicing, may offer greater long-term savings through increased productivity.

Technical Considerations

When using air tools, you need a reliable air compressor, which can be a significant additional investment. Regular maintenance is also crucial to avoid downtime due to mechanical failures. On the other hand, hand tools are relatively low-tech but require skill and patience to master their use effectively. They are also generally easier and cheaper to maintain over time.

Safety and Environmental Impact

Both hand and air tools have specific safety measures that must be followed. Hand tools can cause injuries like strains or blisters without proper technique, while air tools pose risks such as high-pressure air injuries or hearing damage from prolonged noise exposure. Environmentally, hand tools have a smaller footprint, as they don’t rely on electricity or compressors, making them a greener choice.

The choice between hand tools and air tools boils down to the specifics of your woodworking projects. For custom, intricate work, hand tools might be your best bet. For larger-scale operations or when time is of the essence, air tools could enhance productivity and ease the physical strain.

FAQs

Q: Which tools last longer?

A: Generally, hand tools can last a lifetime with proper care, while air tools may require more frequent replacements or parts due to mechanical wear.

Q: Can I use air tools for home projects?

A: Yes, air tools can be great for home use, especially if you undertake large projects or want to save time and effort.

Each tool type has a place in woodworking, and the best choice often depends on the specific needs and scale of your projects.

Matthew Dowell

Matthew, a seasoned builder from a family of craftsmen, leads Tools Trove. His passion for tools and decades of hands-on experience fuel his commitment to providing expert reviews and insightful content. Whether you’re a pro or a DIY enthusiast, Matthew’s guidance ensures informed decisions in the world of tools.