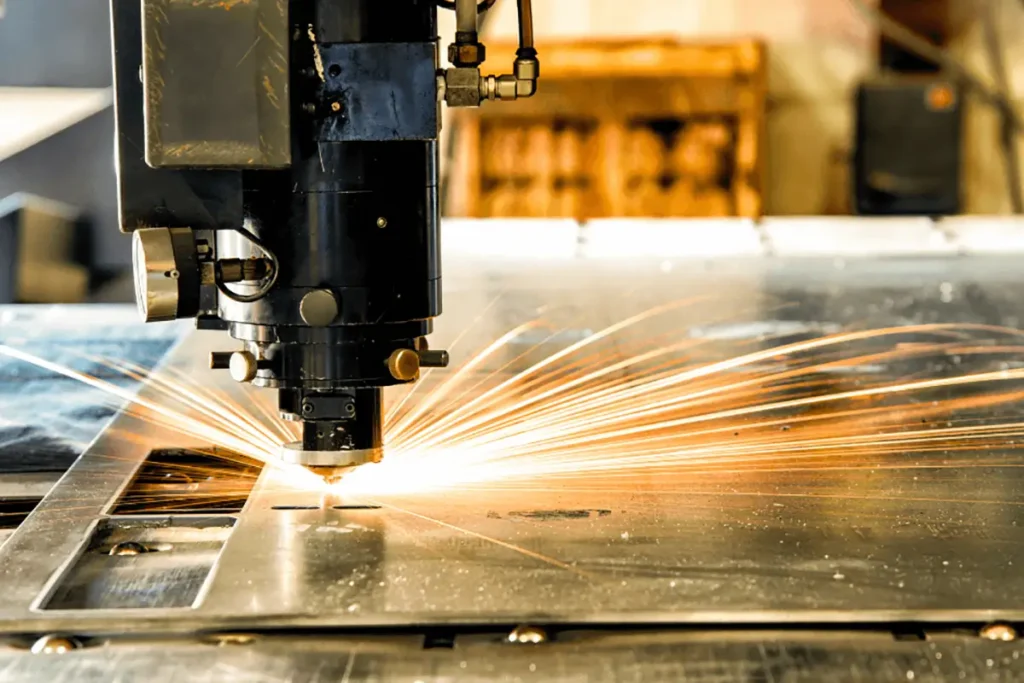

Selecting the right assist gas for laser cutting can be a game-changer. Whether you’re cutting stainless steel, carbon steel, aluminum, or other materials, the assist gas can significantly affect the quality, speed, and cost of your project. Let’s discuss the nitty-gritty of how to choose the perfect gas for your laser cutting needs.

What is Assist Gas in Laser Cutting?

Assist gas is like a sidekick to your laser cutter. While the laser does the heavy lifting by melting or vaporizing the material, the assist gas helps blow away the molten material, keeps the cut clean, and can even enhance the cutting process. Common assist gases include Nitrogen, Oxygen, Compressed Air, and Argon.

Factors to Consider When Choosing Assist Gas

Material Type

The type of material you’re working with is the first factor to consider. Different gases react differently with various materials, and choosing the right one can make or break your project.

| Material | Preferred Gas | Notes |

|---|---|---|

| Stainless Steel | Nitrogen | Prevents oxidation and ensures clean cuts. |

| Aluminum | Nitrogen | Ideal for high-quality, oxidation-free cuts. |

| Brass | Nitrogen | Keeps the edges smooth and clean. |

| Carbon Steel | Oxygen | Enhances cutting speed and efficiency for thicker cuts. |

| Mild Steel | Oxygen | Great for thicker materials but can oxidize edges. |

| Galvanized Steel | Oxygen | Effective but may require post-processing. |

| Mixed Metals | Compressed Air | Cost-effective but may affect cut quality. |

Material Thickness

Thinner materials usually benefit from high-pressure Nitrogen, which helps achieve clean cuts without oxidation. For thicker materials, Oxygen can be more effective as it aids the cutting process by reacting with the material and generating additional heat.

Desired Cut Quality

If you want clean, smooth edges with minimal post-processing, Nitrogen is your best bet. It prevents oxidation and keeps the material surface clean. However, if a slightly oxidized edge is acceptable, Oxygen can be a more economical choice, especially for thicker materials.

Cost Implications

Cost is always a critical factor. Nitrogen tends to be more expensive than Oxygen and Compressed Air, but it can save you time and money on post-processing. Compressed Air is the cheapest option but can compromise on quality.

Cutting Speed and Efficiency

Cutting speed can vary significantly depending on the assist gas used. Nitrogen is excellent for fast, high-quality cuts in thinner materials. Oxygen, on the other hand, can speed up the process for thicker materials by aiding the laser in cutting through the material more efficiently.

Detailed Analysis of Each Assist Gas

Nitrogen (N2)

Benefits:

- Prevents oxidation, ensuring clean edges.

- Ideal for non-ferrous metals like stainless steel and aluminum.

- Helps in achieving high-quality cuts with smooth edges.

Applications:

- Stainless steel, aluminum, brass, and other non-ferrous metals.

- High-precision cutting where edge quality is paramount.

Cost and Equipment:

- Requires high-purity Nitrogen, which can be expensive.

- Additional equipment like nitrogen generators or vaporizers might be needed.

Oxygen (O2)

Benefits:

- Enhances cutting speed for thicker materials by generating additional heat.

- Reduces the power needed from the laser, making it efficient for thick materials.

Applications:

- Carbon steel, mild steel, galvanized steel.

- Projects where slight edge oxidation is acceptable.

Drawbacks:

- Can cause oxidation on the cut edges, requiring post-processing.

- Not suitable for materials where a clean edge is critical.

Compressed Air

Benefits:

- Cost-effective and readily available.

- Suitable for general-purpose cutting.

Applications:

- Suitable for carbon steel, aluminum, brass, and non-ferrous metals.

- Best for projects where cost is a significant factor, and slight quality compromises are acceptable.

Limitations:

- Can cause burrs and discoloration on cut edges.

- Requires clean, dry air to prevent contamination of optical components.

Argon (Ar)

Benefits:

- Inert nature prevents any reaction with the material.

- Provides high-quality cuts similar to Nitrogen.

Applications:

- Specialty metals and materials where Nitrogen may react.

- Situations where the highest quality cuts are required, regardless of cost.

Cost Implications:

- More expensive than other gases.

- Generally used in specialized applications due to its high cost.

Practical Considerations

Gas Purity Requirements

The purity of the assist gas can significantly affect the quality of the cut. For instance, Nitrogen used in laser cutting should be of high purity to prevent any impurities from affecting the cut quality. Oxygen, while more forgiving in terms of purity, should still be relatively clean to ensure efficient cutting.

Equipment and Setup

Using assist gases requires specific equipment. Nitrogen and Oxygen may need generators and vaporizers, while Compressed Air requires compressors and filters to ensure the air is clean and dry. Regular maintenance of this equipment is essential to ensure optimal performance and avoid contamination.

FAQs

What is the best assist gas for cutting stainless steel?

- Nitrogen is typically the best choice for cutting stainless steel due to its ability to prevent oxidation and produce clean edges.

Can I use Compressed Air for high-precision cuts?

- While Compressed Air is cost-effective, it may not provide the high-quality edges required for precision cuts. It’s best used for general-purpose cutting where slight quality compromises are acceptable.

How does material thickness affect the choice of assist gas?

- Thinner materials benefit from Nitrogen, which prevents oxidation and maintains cut quality. Thicker materials may require Oxygen, which helps by generating additional heat and aiding the cutting process.

Matthew Dowell

Matthew, a seasoned builder from a family of craftsmen, leads Tools Trove. His passion for tools and decades of hands-on experience fuel his commitment to providing expert reviews and insightful content. Whether you’re a pro or a DIY enthusiast, Matthew’s guidance ensures informed decisions in the world of tools.